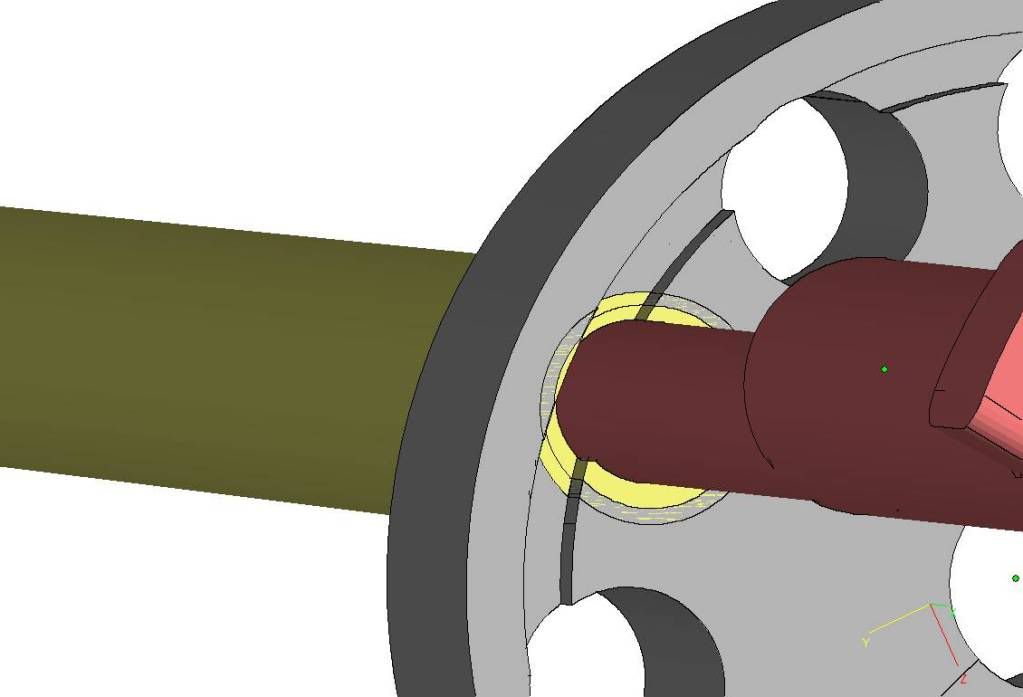

Here\'s a picture(below) so all can see what we\'re talking about. This only shows the BARREL, BREECH RING and BOLT.

I also had a print with a grooved BREECH RING and a grooveless BREECH RING. I assumed the grooveless one was just an extra print in the same way that some other parts have half finished prints as well as completed prints.

I can see that a grooveless BREECH RING can be used, but the barrel still needs a cut out of it for the extractor part of the bolt to go into. If there isn\'t a cut out on the barrel at least, the extractor would stop the bolt going fully into battery.

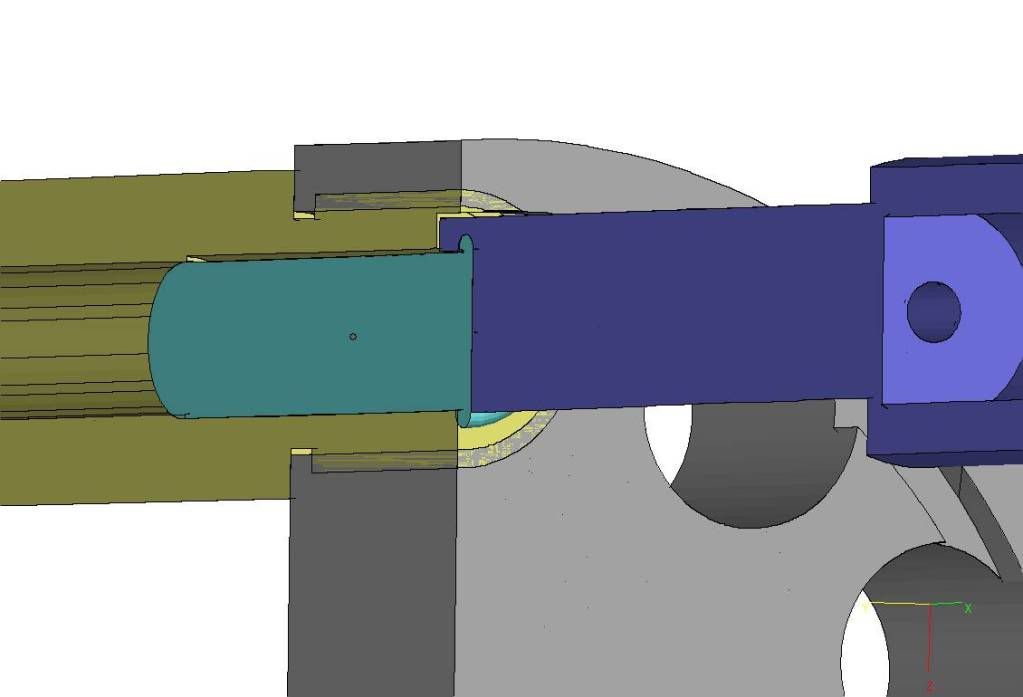

This picture(below) shows the bolt in battery and a round of ammunition in the chamber. As far as I can work out, the whole of the case is supported other than the part where the groove is which is very small (2.5mm long and about 1/3 of the circumference). Is this too much to be unsupported?

I dont see how I can support the extractor any more without a lot of work. One way would be to counterbore the barrel only on the side of the extractor and use the barrel to support the extractor. I dont think this would be viable though.

When you grooved the BREECH RING, did you also groove the BARREL, or was your barrel set further forwards so the cartridge wasn\'t supported all the way round at the rear?

I can also see the small slither of the barrel that you were saying breaks off. I\'ll make sure I remove that if I do it this way. (Thanks)

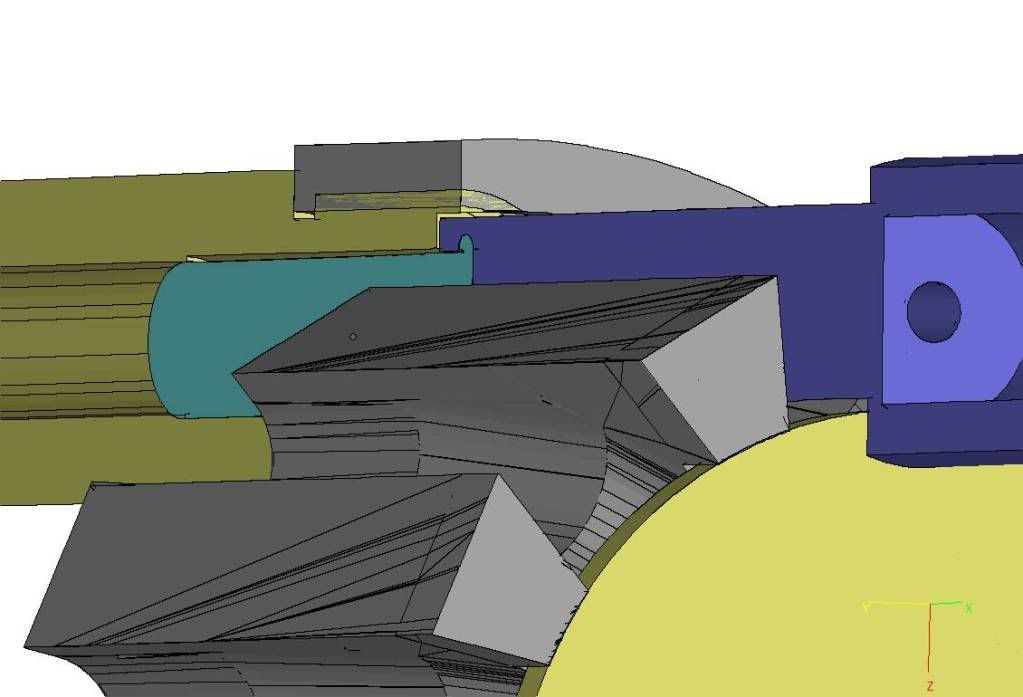

I\'m wondering if the barrel missalignment maybe weakened the extractors somehow on your first version? I\'m definitely going to pin the BREECH RING, PAN and BODY before I fit it in the BODY.

In this picture, I have added the pan and the rim stop. The rim stop limits how far forward the bolt goes (as well as the FRONT CAM)

I thought about turning the BOLTs in one go, but chickened out and had them cast. I didn\'t fancy making up the cutter for the extractor!!

I\'ve not silver soldered anything yet. It\'s one skill I\'ve not got although I might need it at some stage..... Its definitely the way forward if you want nice machined surfaces. My way entails lots of hand finishing. :-(

I think looking back, I\'d have made the main shaft out of hex bar and used a breaching tool to make the central hole on all my center holes. I may also turn a hex on the front bar in order to enable me to tighten it up. (thanks). ;-)